From compact servo-hydraulic bench systems to meganewton class multiaxial test portals, we offer machines for both basic and highly advanced testing. Each system can be customized with the right drive system (servo-electric, servo-hydraulic or linear motors) as well as gripping systems, fixtures and extensometers - for accurate simulation of real-life stresses.

Register yourself

Dynamic fatigue machines

Fast facts

In dynamic fatigue machine used for mechanical testing of materials and components to simulate real loads and investigate strength in tests such as LCF (Low Cycle Fatigue), HCF (High Cycle Fatigue), COD (Crack Opening Displacement) and TMF (Thermo Mechanical Fatigue). With this equipment you can perform both standardized and customized fatigue tests, including other types of dynamic tests, to ensure the quality, durability and safety of structures and products.

Why choose our fatigue testers?

More information about

Dynamic fatigue machines

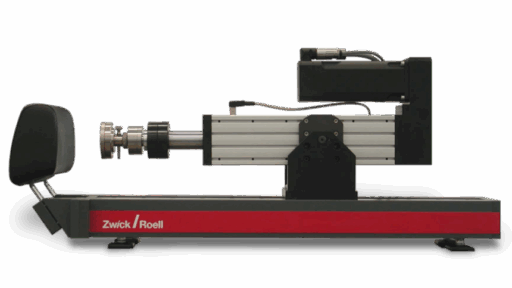

Electromechanical servo actuators for flexible testing solutions

ZwickRoell electromechanical servo test actuators are versatile and can be used as flexible testing machines for a wide range of applications. They are ideal for both tensile and compression testing, and can be easily integrated into various test fixtures and customized to specific needs.

With these actuators, you can perform everything from material testing and component testing to tests on finished products. They are also ideal for verifying individual production steps such as joining, press-fitting and assembly.

In addition, the actuators can handle fatigue testing with large stroke lengths, making them an excellent choice for advanced testing environments where high precision and repeatability are essential. Powered by an AC motor, no hydraulics are required, making them easy to move between different applications.

With a ZwickRoell servo test actuator, you get a reliable, energy-efficient and user-friendly solution to meet today's high demands on testing and quality control.

Advantages of the EM Actuator:

Vibrophores for fatigue testing

Vibrophore - energy-efficient resonance testing machine for fatigue and static tests

ZwickRoell's Vibrophore is a high-frequency testing machine that combines resonance technology and electromagnetic drive to perform dynamic and static tests with high precision and low energy consumption. The machine is ideal for determining fatigue strength (HCF), service life and fracture behavior of materials and components.

In the latest generation, the Vibrophore can also be used for static tensile and compression tests up to 1,000 kN, making it a truly multifunctional testing solution for both R&D and quality assurance.

Typical applications:

- Fatigue testing of bolts, crankshafts, piston rods, reinforcing steel and concrete

- Fracture mechanics tests (CT/SEB specimens)

- Production testing and lifetime simulation of dynamically loaded components

Vibrophore combines high performance with energy savings and low operating costs, making it a cost-effective choice for high-volume testing and advanced materials analysis.

ZRS helps you all the way - from needs analysis to installation, calibration and support.

Advantages of ZwickReoll Vibrophores:

LTM - Electrodynamic testing machine

LTM series are electrodynamic testing machines with patented linear motor technology, developed for both dynamic and static testing. The machines have low moving mass and offer outstanding control and stability - ideal for fatigue, tensile, compression and bending testing in the 1-10 kN force range.

Thanks to its oil-free and quiet drive technology, the LTM is particularly in demand in industries with high demands for a clean environment and low noise levels - such as medical technology, plastics industry and academic research.

Typical uses:

- Fatigue testing of plastic, metal and fiber composites

- Standardized testing of implants: hip, knee, dental

- Component testing with flexible T-track platform

- Functional and strength testing in R&D and education

With testXpert and testXpert R, you get an intuitive user interface with complete control over all test procedures - from configuration to data collection and analysis. The machine is delivered complete and ready to integrate into laboratories and production environments.

ZRS offers advice, installation, training and service - we help you get the most out of your LTM machine.

Advantages of LTM:

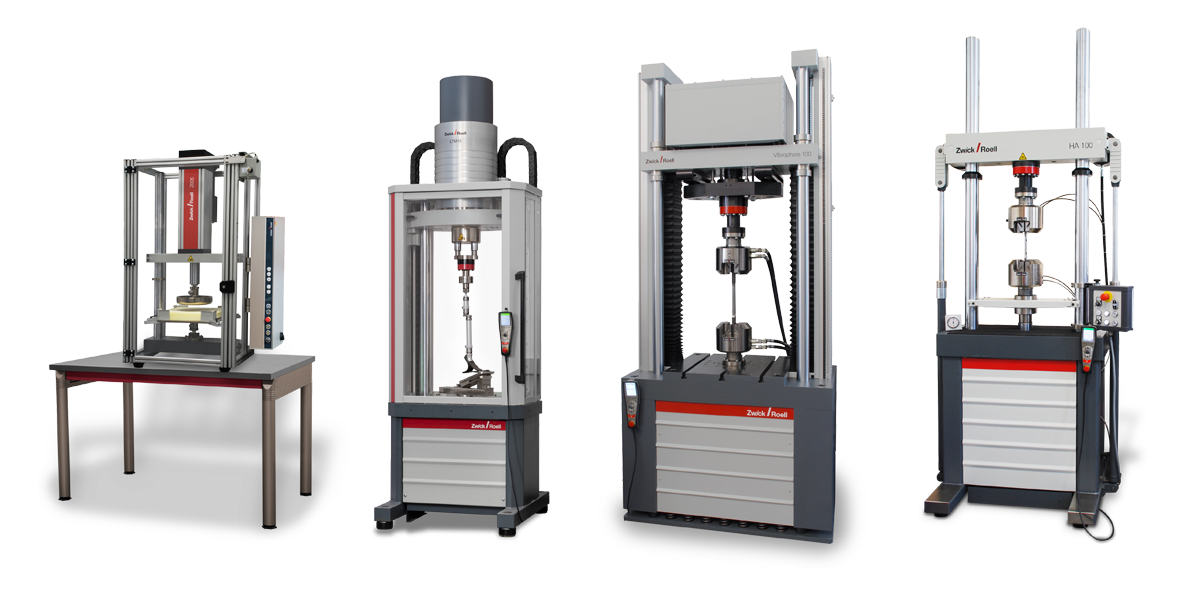

Servohydraulic testing machines for fatigue testing

Servo-hydraulic fatigue test systems - maximum stiffness and reliability in dynamic testing

ZwickRoell servo-hydraulic test frames are specifically designed for fatigue testing and crack growth analysis, where high measurement accuracy and frame stiffness are essential. They are used to determine material properties under cyclic loading, including:

- High-cycle fatigue (S-N) / Wöhler curves

- Low cycle fatigue (LCF)

- Fracture mechanics and fracture propagation

The test actuator can be mounted above or below the test area depending on ergonomics and type of test. The actuator has hydrostatic bearings, which provide very low friction, minimal wear and long life - even at high loads and frequencies.

The systems are powered by separate hydraulic power packs, available in different power classes to adapt to your needs. With extremely high frame stiffness and a precision-controlled tool and load cell mount with guide pin and flange, exceptional alignment and repeatability is achieved in all test procedures.

ZwickRoell test systems always come with testControl II electronics and testXpert software, ensuring precise control, data collection and analysis - integrated and user-friendly.

ZRS helps you every step of the way - from configuration to installation, calibration and long-term service.

Advantages of servo-hydraulic testing machines:

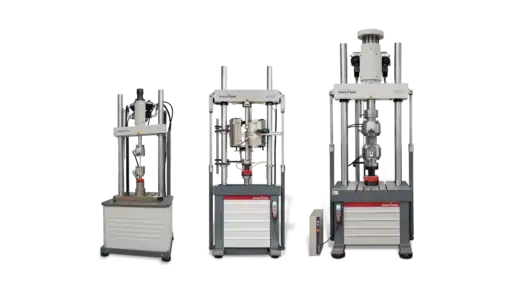

HTM - high speed tester for high strain rate

HTM - high-speed tester for materials with crash data and strain rate requirements

ZwickRoell's HTM series are advanced servo-hydraulic testing machines for high strain rates, ideal for applications where the fracture behavior of the material is affected by the loading rate - such as in crash, impact or rapid deformation.

With test forces from 25 kN up to 160 kN and a maximum piston speed of 20 m/s, the HTM machines enable reliable testing of materials and components under real load conditions.

The system comes complete with hydraulic power units, high-precision sensors, testControl electronics and testXpert software, providing a seamless and integrated test solution - from sample clamping to data analysis.

Thanks to its wide speed control, HTM can be used for both slow and extremely fast test runs, making it ideal for developing constitutive models, simulations and safety calculations in the automotive, aerospace, packaging and advanced materials research industries.

ZRS offers consulting, installation, service and calibration - we help you all the way from needs analysis to finished test solution.

Typical uses include:

Learn more about

Dynamic fatigue machines

-

-

Whether you work on standard tests or complex research assignments, you get a stable and scalable solution, supported by experts who understand both industry requirements and testing techniques.

-

If you choose a dynamic fatigue machine from ZwickRoell you get a solution with the highest precision, reliability and ease of use, as well as access to global support and expertise to help you optimize your testing processes and meet future requirements