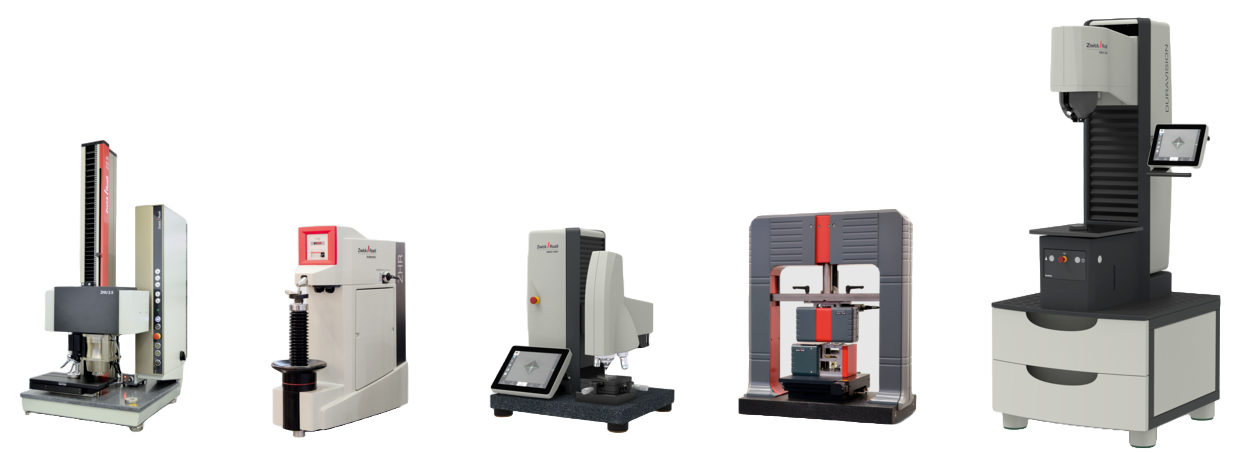

Full range of instruments

Our product line includes a complete range of instruments to perform hardness testing. The hardness testers are for use to test the hardness of metals, plastics, rubber and specialty materials to all the major and globally accepted standards. ZwickRoell's hardness testing solutions range from standard manual instruments to fully automated hardness testers.

ZRS Service Department helps you with installation and calibration. We are accredited by SWEDAC to perform calibration on hardness testers according to the following standards: ASTM E10:18, ASTM E18:18A, ASTM E384:17, ASTM E92, SS-EN ISO 4545-2, SS-EN ISO 6506-2, SS-EN ISO 6507-2 and SS-EN ISO 6508-2

Univesal hardness

ZwickRoell Emco-TEST universal hardness testers cover an unrivaled wide load range from 0.3 to 250 kgf and 3-3000 kgf. The electronically controlled test cycle provides a wide range of test methods. Brinell, Vickers and Rockwell methods can be measured in accordance with EN ISO and ASTM standards, even carbon fiber materials can be measured for hardness. Knoop and plastic tests can also be performed. Thanks to its robust construction, the DuraVision G5 is particularly suitable for use not only in a dirty production environment but also in the laboratory for quality assurance purposes.

Rockwell Hardness Tester

The various ZwickRoell hardness testers in the Rockwell product group are used for classical Rockwell methods, superficial Rockwell methods and depth measurement methods for hardness testing on metals. They are also suitable for hardness measurement on plastics. We offer two models of Rockwell testers deadweight load and servo-loop load with force transducer. The load range extends from 0.3 to 250 kg.

Vickers hardness tester

With ZwickRoell Emco-TEST's Vickers tester, Knoop and Brinell tests can also be performed in the load range between 0.25 gf and 62.5 kgf. The Vickers tester is characterized by the innovative user guidance system for intuitive and easy operation. The test cycle from setting the indentation position to displaying the hardness value is always carried out fully automatically, eliminating operator effects to the greatest extent possible.